Making a cardboard boat seems simple enough; however, during Arroyo Grande High School’s Greek Week, this task is taken to its competitive extreme. Each grade level competes for Greek Week points by creating a boat and racing from one end of the pool to the other and back. Additionally, there are individual teams that create boats separate from the Greek Week teams. This school tradition leads many to wonder, “How do you make the best cardboard boat?”

I started making the boat because my physics teacher, James Colgan, said, “Someone should make a boat,” and then a few people in the class stepped up.

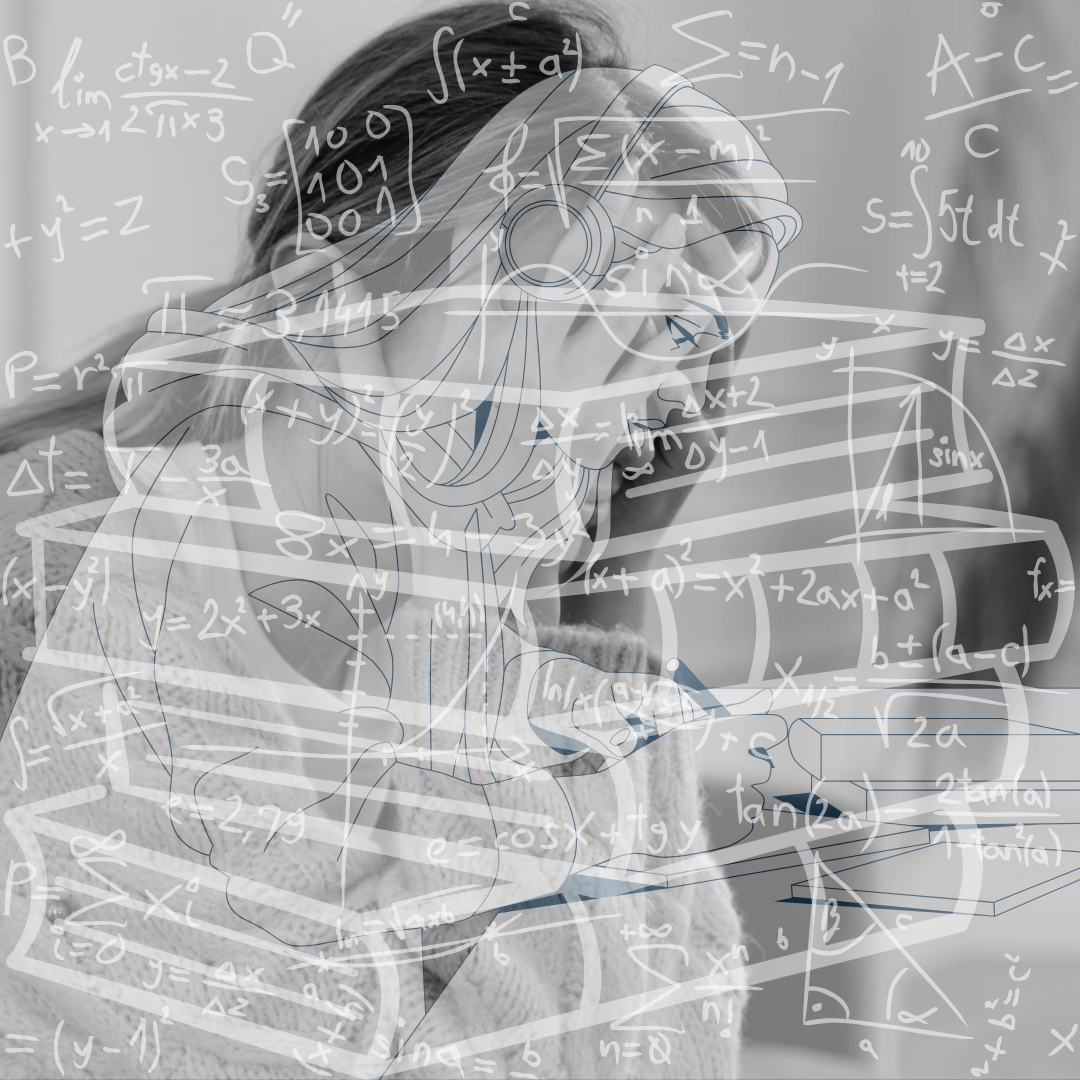

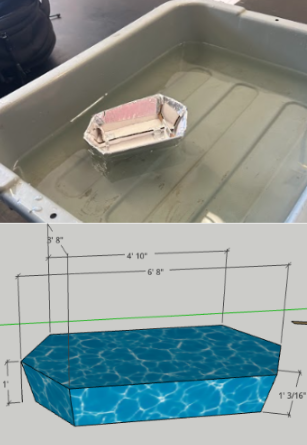

I started with the design. It’s important not to jump into building a boat without a plan, because even though plans change, having a clear starting point can help, especially if you’re working with a team.

In my design, I decided to focus on building a large boat; however, this choice led to a few consequences. A large boat makes rowing more difficult for people inside, decreases the strength of the boat, and makes the build much more time-consuming.

Once my design was complete, I decided it would be helpful to create a prototype. Making this smaller boat influenced my build strategy and my design, but building the smaller boat turned out to be very different from building the large boat.

Following the prototyping is the most important and time-consuming part: the building process. It’s important that you give yourself time to

construct the boat and adapt as needed. In my experience, the process took many more hours than I expected, and I ended up with significantly less time than I had anticipated to accomplish my design goals. Building the boat in one day limited my ability to reinforce the cardboard with multiple layers, because cutting the cardboard to such a large template was tedious. I’d recommend giving yourself at least a week to dedicate specifically to building. Having additional helpers during the construction phase could certainly make this process faster and more enjoyable, in addition to having ample time.

Samuel Jurcazak (’26), who played a role in the boat-duct taping process, has experience with boat building.

“I made a boat last year, but this year with this group it’s a lot more methodical and we’re using more processes to figure out the design of it,” Jurcazak said.

Compared to his experience last year, Jurcazak said we’ve taken a much more scientific approach to constructing the boat.

“Last year, when I was part of making a boat, we kind of just eyeballed everything, and we didn’t really use any measurements,” Jurcazak said. “This time it’s much more of a process.”

Some people found my slightly science-based approach unnecessary.

“I don’t think what John Purvis is doing with his boat is necessary,” Nash Fernsler (‘26) said. “There’s no need to calculate buoyancy, just do a solid boat and then paddle.”

Nash has some room to talk, having won the Greek Week boat regatta last year for the juniors.

“I think John Purvis won’t do very well, but that’s just speculation,” Fernsler said.

Friday, May 23rd, is the last day of Greek Week and the day of the anticipated boat regatta events. Students cram into the pool deck dressed in the class colors to witness boat racing greatness.

The first event was the individual boat race, where the boat I made would be featured. Atticus Mackoui (26’) and Asher Reynolds (26’) rowed the boat, starting strong, reaching the other end of the pool before any other group. A few of the boats had already sunk, and as Mackoui and Reynolds reached the turning point, the boat began to capsize. Flipping the boat back up, the rowers raced back to the starting point, falling out once again meters away from the end and dragging the boat the remaining distance. The duo got first place, however, the boat struggled to make it there.

I’d recommend giving yourself more time, duct tape, and cardboard than you think you’ll need before making a boat, and if you have all that along with what I outlined, you’ll make a successful boat.